The safest way to work on electrical equipment is to de-energize and “lock-out” the equipment. But how do you avoid the electrical hazards while racking a breaker?

Fortunately, there are controls that can be added to safely rack medium voltage breakers.

The remote racking equipment from Power Precision allows viewing and controlling the racking of breakers from a safe distance – outside the arc flash boundary.

Touch screen operator interface

Breaker movement is controlled by a touch screen graphical interface. The controls prompt the operator through a sequence of steps and checks to perform the racking process safely. The control interface is mounted safely outside the arc flash boundary. Real time information such as the breaker tilt/level measurements and breaker lifting resistance are displayed in real time. Any alarms or faults are immediately displayed.

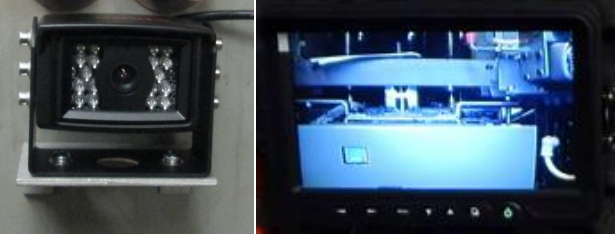

Live Video Monitoring

Using a low light Infra-red camera, the operator is able to view the breaker position and movement on a live flat screen video monitor while the breaker door is closed. The video monitor is mounted next to the operator interface outside the arc flash boundary.

Breaker Tilt Monitoring

A dual axis analog monitor continuously transmits breaker the level/tilt status of the breaker for the operator to monitor and to automatically stop movement when outside programmed limits.

Breaker Lift Resistance

The resistance of the breaker lifting mechanism is continuously monitored. Resistance exceeding typical limits provides an alarm or trip.

Lifting Motor and Controls

A new racking motor/clutch assembly is provided to control the motor, clutch and breaker lifting mechanism from the remote operator station. The new racking motor/clutch assembly is equipped with a variety of sensors for monitoring during operation.